Q +A with CIAC PD member Layfield Group Ltd.

August 30, 2022

We took some time to speak with CIAC Plastics Division member Layfield Group to get to know the company. In the following Q+A we speak about their dedication to sustainability, product design, innovative new products, and pressures facing the industry.

For anyone who isn’t familiar, can you tell us a bit about Layfield?

Layfield Group is a vertically integrated extrusion, conversion, fabrication, distribution, and installations company. For over 40 years we have provided tailored solutions that give our customers peace of mind, protect our communities, the environment, and our families. Our Mission is to Protect.

While our Flexible Films division delivers customized packaging solutions for the food, pet food, industrial and medical markets, our GeoPro division supplies, fabricates, and installs geosynthetics primarily for water preservation, soil reinforcement, and environmental containment. Our approach is, avoid cutting corners and act ethically with an uncompromising eye for quality.

With locations in British Columbia, Alberta, Ontario, Washington, and California we are a premium provider for a wide variety of customers and industries.

Layfield is focused on sustainability; can you tell us about some of the innovative products you offer and anything you may be working on currently?

Layfield is considered an environmental solutions company, helping protect our environment with low carbon options for wastewater containment, flood mitigation, environmental protection, as well as food and medical preservation products.

In the food & medical packaging sector, we face unprecedented pressures to create better end-of-life plastics. Layfield along with many other plastic processors are working to increase our portfolio of sustainable solutions. Where we differ from some producers is that we believe the circular economy, with respect to plastic, should include mechanical and advanced recycling along with “landfill and waterway friendly” plastics.

Consistent with many plastic processors, Layfield’s sustainable packaging strategy is also aligned with both the US and Canadian Plastic Pact targets. Our strategy has been to increase our Store Drop Off, pre-qualified, How2Recycle® line of products, as well as introduce PCR product lines.

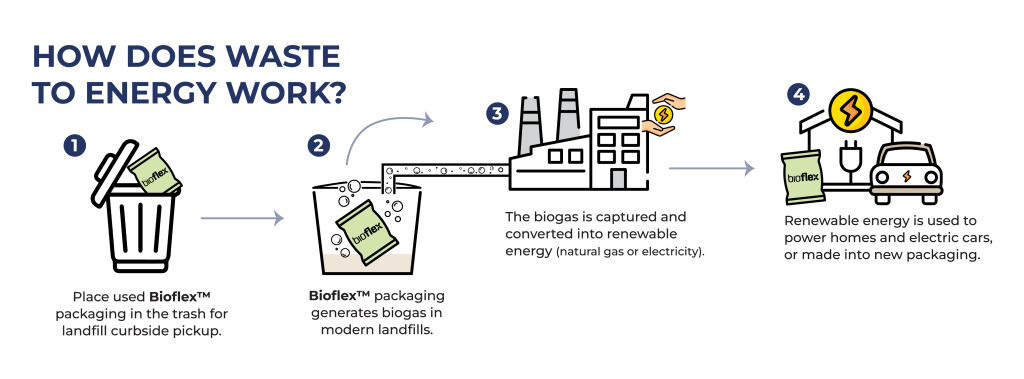

What differentiates Layfield from many conventional processors is, while we continue to offer a solution that is recyclable, we also offer or a waste to energy solution. We have trademarked this solution as Bioflex™. In addition, we want to share our expertise and test results, even collaborate with competitors to help advance the technology. Improving our industry and reducing our environmental impact. https://www.bioflexpackaging.com/

The plastic we generally produce starts as natural gas, thus we feel “full circularity” means it should return to natural gas in a contained environment to ideally offset coal or other more harmful energy inputs. Every KG of Bioflex™ has the energy potential to power a small electric car for 25KM’s. If it gets recycled once or twice along the way that’s great but, statistics show, eventually it will likely end up in a landfill. Having a landfill and waterway friendly solution is just good insurance. Should Bioflex™ escape the recycling stream, or recycling does not make sense, Bioflex™ can disappear through anaerobic biodegradation and can be converted into energy.

Despite idealism, we strongly believe that even conventional plastics are the most environmentally friendly option for virtually any application, however; we believe Bioflex™ is the ultimate no compromise solution. Generally, when you substitute plastic for another material, you cause more damage to the environment. If our biggest environmental challenge as a society is global warming, we don’t want to substitute plastic with more harmful materials.

While we await clear guidelines and hope for common sense policy, we believe there is going to continue to be a gap between recycling and landfilling.

What are the challenges in designing and developing increasingly sustainable product offerings?

Frankly, it is a bit of a mess throughout our value chain with all the competing agendas and priorities. Many of these priorities are rooted on idealism and not on practical empirical data.

We want to do what is right without a green-washed or solely profit-minded end-of-life solution. We face many challenges in designing and developing increasingly sustainable product offerings. It’s disheartening when the better solution is opposed because it does not match a competing or more idealistic environmental solution with no practical end in mind.

Adding to the environmental debate over which way to go are the “rightful skeptics”. In the past, there have been other solutions that have greenwashed their solutions not fully disclosing the downsides of their technology (creation of microplastics, not practically recyclable, compostable etc.).

Technological limitations upstream or downstream in the value chain also create massive hurdles. Theory and practice don’t always align. Also, unclear policy direction hampers investment in equipment and raw material as these gambles are generally not in the thousands they are in the millions or in some cases billions.

We work closely with our partners to meet the demand of sustainable products needed today, while monitoring the evolution of the market’s forecast. Staying connected with multiple sustainability organizations such as, the Chemistry Industry Association of Canada (CIAC), Sustainability Packaging Coalition (SPC), Pet Sustainability Coalition (PSC), and Western Plastics Association (WPA) help us stay abreast of emerging government legislations and society’s expectations.

What other pressures does Layfield face?

Our industry, particularly in North America is at an exceedingly difficult crossroads economically and environmentally. We face extreme pressure from foreign competitors who have less regulations, cheaper labour, less expensive property, and now lower-cost resin materials which are mainly produced in North America. Foreign competitors and distributors seem to do nothing or very little to further these environmental initiatives and it falls on the beleaguered North American producers. It is frustrating that we can’t come together as a society to further our continental environmental and economic agendas.