Sustainability Report

ABOUT RESPONSIBLE CARE

The chemistry and plastics sector, including all CIAC members, is committed to continuously improving environmental, health, and safety performance year after year. At the core of these efforts is Responsible Care®, a made-in-Canada initiative. Established in 1985, Responsible Care is now practiced in 73 countries and embraced by 96 of the world’s 100 largest chemical producers. Responsible Care companies uphold the ethic to “do the right thing and be seen to do the right thing.” Our dedicated members continually innovate to develop safer, greener products and processes while striving for ongoing improvements in environmental, health, and safety performance.

CIAC Plastics Division members are also committed to eliminating plastic pollution caused by resin loss during production and transportation. Through Operation Clean Sweep™ (OCS)—an international environmental stewardship program—the Division helps plastic resin handlers adopt modern containment practices. The CIAC Plastics Division leads the implementation of OCS in Canada, ensuring responsible practices across the industry.

YEARS OF RESPONSIBLE CARE

COUNTRIES PRACTICING RESPONSIBLE CARE

OF THE WORLD’S 100 LARGEST PRODUCERS

Through our membership on the International Council of Chemical Associations (ICCA), CIAC is committed to accelerating progress towards the 17 UN Sustainable Development Goals (SDGs) and is working towards identifying association-specific targets. The UN SDGs that are most material to the chemistry sector are identified throughout the report.

MESSAGE FROM THE VICE-PRESIDENT, RESPONSIBLE CARE®

As we celebrate the 40th anniversary of Responsible Care in 2025, we reflect on the evolution of this pioneering initiative and the chemistry and plastics sector’s progress in advancing sustainability. Since its launch in Canada in 1985, Responsible Care has continuously adapted to new challenges, raising the bar for safety, environmental stewardship, and community engagement. In recent years, this commitment has expanded to include Indigenous Engagement Code elements and principles addressing equity, diversity, and inclusion—reinforcing that Responsible Care is more than a program; it is a dynamic, guiding ethic that shapes our industry’s actions.

While technological advancements have surpassed what we could have imagined in 1985, challenges like addressing climate change and a circular economy remain a work in progress. This is the nature of long-term transformation—industries, communities, and innovations evolve at different paces. Yet, one thing has remained constant: the chemistry and plastic sector’s commitment to the fundamental principles of Responsible Care. No initiative lasts four decades without delivering real value, and time and again, Responsible Care has proven to be a trusted framework for responsible decision-making in an increasingly complex world.

As we navigate this period of transition, we recognize that with new challenges come new opportunities. The principles of Responsible Care provide a steady foundation, ensuring that we continue to "do the right thing and be seen to do the right thing." Looking ahead, we envision a future where Responsible Care continues to evolve—just as it has for the past 40 years—guiding industry leaders in making responsible choices that benefit people, communities, and the planet. I can only imagine what the highlights of the 2050 report will reveal.

VICE-PRESIDENT, RESPONSIBLE CARE®

RESPONSIBLE CARE® AWARDS

Photo left to right: Kara Edwards, Tyler Yates (GATX), Jeff Nee (GATX), Alicia Pope (Inter Pipeline), Alicia Chapman (Inter Pipeline), Mike Bélanger, Emily Fattore (ERCO Worldwide), Ron Koniuch (CCC Sulphur Products), Dr. Ronda Gras (Dow Canada), Diego Ordonez (Dow Canada), James Brown (Dow Canada), and Bob Masterson.

OPERATIONS AWARD

Stewardship Award

Accountability Award

OCS Company of the Year

Company of the Year Award

Jean Bélanger Award

Women in Chemistry Award

Excellence in Partnership Award

Excellence in Partnership Award

Plastics Contributor of the Year

President’s Award

President’s Award

REDUCING INEQUALITIES

In 2024, 3M launched its 25 Women in Science initiative in Canada, which seeks to recognize the scientific work of women who have generated a positive impact on their communities, country or science at large. 2024’s theme was Environmental Sustainability with projects on circular economy, carbon footprint reduction, water management, energy, land use, climate change and ecosystem protection, among others, highlighted.

BASF has been named one of Canada's Best Diversity Employers for the second consecutive year. This award recognizes BASF for its employee-centric programs and ongoing commitment to fostering a diverse, equitable and inclusive workplace. Mediacorp, the nation's largest publisher of employment periodicals, cited BASF for its noteworthy diversity and inclusiveness programs, which create a sense of true belonging in the workplace and drive forward a culture where employees feel valued, respected, and supported. These include access to 13 employee resource and development groups and BASF’s mental health and wellness support programs.

Methanex sees equity, diversity, and inclusion (EDI) as a strength that drives their competitive advantage. To foster an inclusive workplace, they support Employee Resource Groups (ERGs)—voluntary, employee-led groups that create community and advocate for historically disadvantaged groups.

To ensure consistency and impact, they’ve developed an ERG toolkit that provides guidance on forming and maintaining ERGs, defines roles and responsibilities, and encourages leadership involvement. Each ERG receives support through a Leadership Sponsor, dedicated budget, and time during work hours for planning and events.

Currently, their ERGs include Ascend Women’s Group, the Asian Professional Network, and Methanex Pride, supporting women, Asian professionals, and LGBTQIA+ employees, respectively.

Engaging Communities

In May and June 2024, DuPont Canada sponsored build days with Habitat for Humanity Hamilton, Quebec and Kingston Limestone Region. Enthusiastic DuPont volunteers from their manufacturing sites, R&D and head office supported the construction of homes for very deserving families. Many municipalities are experiencing serious housing shortages, particularly affordable housing. Participating in and supporting a Habitat build helps deserving people have affordable housing in the community.

Inter Pipeline (IPL) took significant steps in fostering relationships with Indigenous communities by signing three relationship agreements in Alberta’s Heartland region in 2024. The first agreement was signed on August 21 during Treaty Days with the Alexander First Nation. Members of IPL’s Executive Leadership Team participated in a Pipe Ceremony, enjoyed traditional dances, and engaged in a gift exchange between leaders, experiencing a truly remarkable day. The second agreement was signed in October with the Kehewin Cree Nation at a smaller, more private event held at a local restaurant. The leadership team had the privilege of meeting with Chief and Council members to formalize this important relationship. The third agreement was signed in November with Bearspaw First Nation and saw a contingent of IPL leaders and the Bearspaw Chief and Council come together to solidify the growth and development of the relationship between the Nation and the company.

Lanxess’ West Hill, Ontario manufacturing facility received the 2024 Pollinator Advocate Award at the North American Pollinator Protection Campaign Conference in Washington, DC. The Lanxess facility, which invented calcium sulfonate complex greases used in a variety of industrial manufacturing, wind turbine, nuclear generation and food grade applications, encompasses 24 acres of forest with urban wildlife. The team at LANXESS has embraced the surrounding ecosystem and has become highly engaged in habitat restoration, involved with local environmental activities and causes, and implemented a community outreach and education program.

For the second year in a row, KRONOS Canada took part in a cycling challenge on July 6, 2024 to support the mission of the Centre 4 Poches. For more than 30 years, the Centre 4 Poches has been providing support to families with children with an intellectual disability or an autism spectrum disorder (ASD), with or without a physical disability. Despite uncertain weather, their team of 31 cyclists wearing KRONOS colours traveled distances of 38, 80 or 110 km in the area around Varennes and Boucherville, QC. The company was proud to announce that, with their help and the contribution of the KRONOS Cares program, they raised $30,030 to support the mission of the Centre 4 Poches. The event is also a great way to promote health and encourage physical activity among KRONOS employees and the community.

Husky Technologies continues supporting and inspiring youth in robotics and engineering through local high school robotics team sponsorship.

Husky Technologies is a long-time sponsor of Humberview Secondary School’s robotics team, the Alpha Dogs. Established in Bolton, Ontario in 2013, the Alpha Dogs work together to engineer robots and compete in various tournaments and challenges against other schools across North America. The students also engage within the robotics community by sharing their learnings and providing mentorship to other robotics teams.

Reducing Emissions

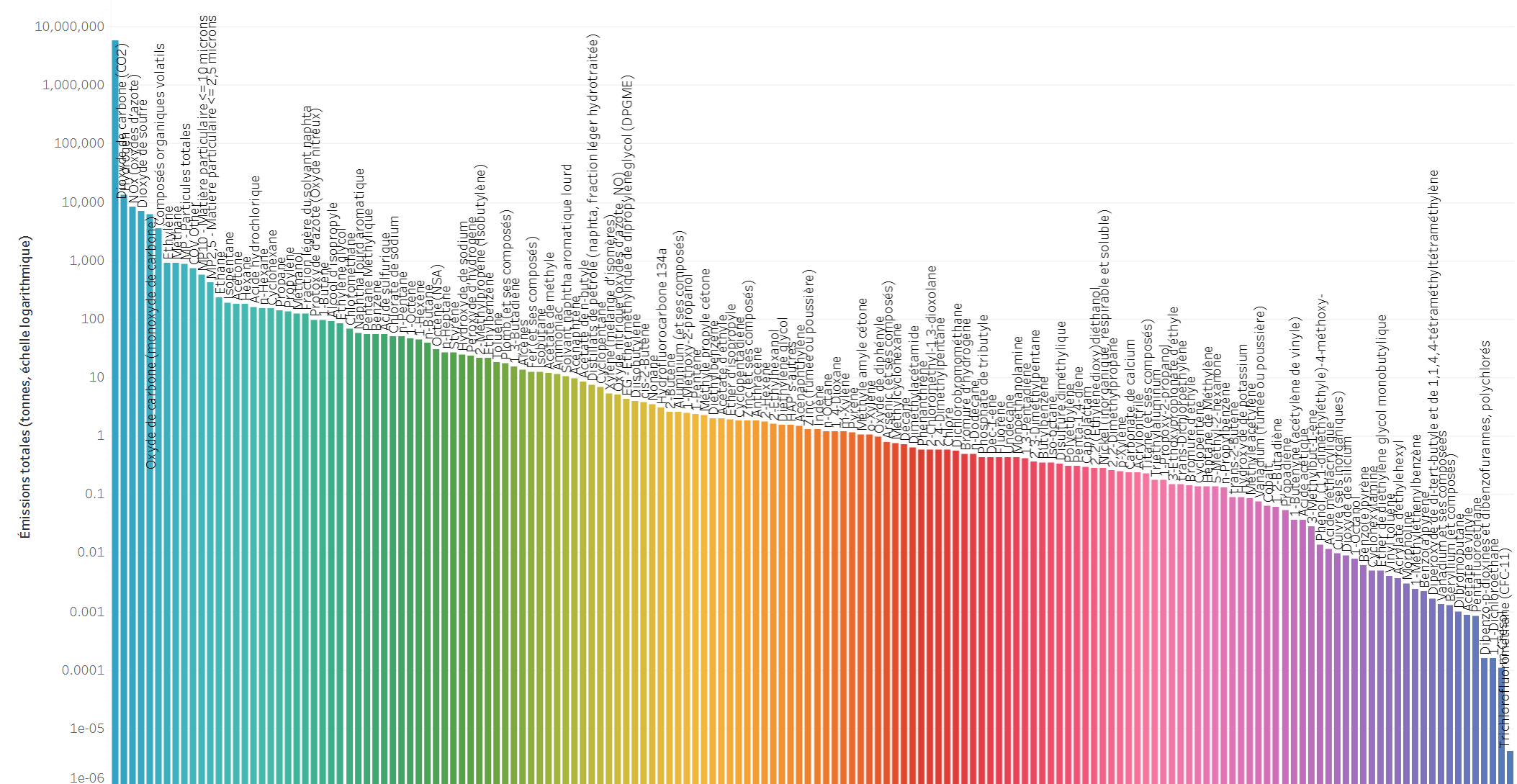

Since 1992, CIAC has and continues to collect data through its National Emissions Reduction Masterplan (NERM) survey on chemical emissions by members to air, water, and land. As shown in Figure 1, in 2023, 162 substances were reported out of 374 total substances on the modernized NERM substance list, and only 24 substances had emissions over 100 tonnes. Since NERM’s inception, CO2 has been consistently ranked the highest emitted substance.

Figure 2 zooms in on some of the top chemicals of interest across our membership in 2023. Hydrogen is the second highest substance emitted this year second only to CO2, and is a harmless gas made as a byproduct of chlor-alkali and electrochemical manufacturing processes. Oxides of nitrogren (NOx), sulphur dioxide (SO2), carbon monoxide (CO) and volatile organic compounds (VOCs) are all light gas molecules which are typically products of petrochemical manufacturing or the burning of fuels like natural gas. Ethylene is a product of petrochemical refining and is used to produce more complex products like polymers. Total particulate matter (TPM) is an air contaminant which is a component of smog, and can take the form of dust, smoke or soot from all manner of processes. Finally, methane and ethane are products of petrochemical refining and use, and are the main constituents of natural gas.

Outpacing a steadily growing CIAC membership, yearly greenhouse gas emissions have decreased 23 per cent since 2005, measured in tonnes of CO2 equivalent. Figure 3 shows the successes that our members have had eliminating harmful ozone-depleting emissions such as Chlorofluorocarbons (CFCs) and Hydrofluorocarbons (HCFCs). Since the beginning of 2023, HFC 134a has also been phased out of use, keeping the equivalent of over 200,000 tonnes of CO2 out of our atmosphere. Our members continue to explore and invest in new technologies, like Carbon Capture, Storage, and Utilization, to further reduce their carbon footprint.

Benzene, toluene, ethylbenzene, and mixed isomers of xylenes make up BTEX, a group of aromatic VOCs commonly analyzed together to provide a well-rounded picture of aromatic VOCs that are present in most urban areas. Figure 4 shows that our members have brought emissions of this category down to a 5 year low in 2023, but more work is ongoing in collaboration with all levels of government and Indigenous communities to further reduce these emissions, particularly benzene, and improve air quality in our members' communities.

The Air Quality Management System (AQMS) is a joint effort by federal, provincial, and territorial governments to reduce emissions and pollution levels of harmful air contaminants (criteria air contaminants or CAC), aiming to protect human health and the environment. Built on collaboration, accountability, and transparency, the AQMS was developed with input from industry, non-governmental and Indigenous organizations, and CIAC. CIAC continues to monitor its implementation and participate in its ongoing improvement.

The Canadian Ambient Air Quality Standards (CAAQS) are a key part of the AQMS, setting targets for pollutants like nitrogen dioxide (NO2), sulfur dioxide (SO2), fine particulate matter (PM2.5), and ozone (O3). As seen in Figure 5, new members from 2019-onward brought new emissions. Despite the significant increase in the number of emitting sites since 2005, CIAC members have seen a 10 per cent decrease in total CAC emissions membership-wide, but this is only part of the story.

Figure 6** digs deeper into SO2, an important contaminant to monitor as it is the main component of acid rain and can contribute to smog as well as soil and ocean acidification. CIAC members have shown great success at reducing these emissions by switching to cleaner-burning fuels and implementing new emissions reduction technologies at the source. Since 2005, the average CIAC member facility has emitted 30 per cent less SO2 on average, with some long-time members cutting their emissions by over 90 per cent. With new sites coming into operation in 2019, CIAC and its member companies are once again making SO2 reduction a priority.

**Figure 6 differs from CIAC’s 2023 report due to the inclusion of a new member. This member joined in 2019 and began reporting emissions then. While the data shows an increase in SO2, when we retroactively track the new company’s emissions back to 2005 using National Pollutant Release Inventory (NPRI) data, SO2 is seen as decling.

INDUSTRY, INNOVATION AND INFRASTRUCTURE

In 2024, Shell Canada Products announced its final investment decision for its Polaris project, a carbon capture project at the Shell Energy and Chemicals Park in Scotford, Alberta. The project will capture approximately 650,000 tonnes of CO2 annually from the Shell-owned Scotford refinery and chemicals complex.

In 2024, BASF and Exterra Carbon Solutions signed a memorandum of understanding to explore a commercial-scale carbon capture and storage (CCS) project in Quebec. The strategic partnership combines BASF’s OASE® gas treatment technology with Exterra’s Reactive Oxide to Carbonate System to help decarbonize hard-to-abate industries like cement, steel, gas-to-power, and waste-to-energy—sectors responsible for nearly 20 per cent of global CO₂ emissions (IEA). This collaboration aims to cut emissions, support Quebec’s decarbonization goals, and improve environmental quality.

As the world moves toward decarbonization, hydrogen is emerging as a key solution for achieving net-zero emissions. When used as a fuel, hydrogen produces only water vapour, making it a powerful tool in the fight against climate change. It also enables energy storage, balancing intermittent supply from renewables like wind and solar, and plays a crucial role in decarbonizing hard-to-electrify sectors such as heavy industry and transportation.

ERCO repurposes hydrogen by-products to support clean energy infrastructure. In partnership with HTEC, it is enabling a hydrogen plant in North Vancouver to supply low-carbon transportation fuels. ERCO is also working with Enbridge Gaz Québec on a major green hydrogen project in Gatineau, creating a dedicated pipeline to connect production with local demand. These initiatives drive innovation, cut emissions, and advance a sustainable future.

Methanex has agreed to invest in a Preliminary Front-End Engineering Design (Pre-FEED) study for carbon capture, utilization, and sequestration (CCUS) at its Medicine Hat, Alberta facility. Partnering with Entropy, the project will integrate Entropy’s modular post-combustion carbon capture technology with Methanex’s manufacturing expertise to convert some captured CO2 into additional methanol. If a final investment decision is made, Entropy will construct and own the capture equipment, while Methanex will supply utilities, build tie-ins, and operate the system once commissioned.

The project aims to capture approximately 400 tonnes of CO2 per day and represents an investment of about CAD $100 million (~USD $75 million), with Entropy contributing the largest share. The initiative is expected to generate around 200 construction jobs and several permanent positions once operational. Additionally, approximately 50,000 tonnes of methanol will be produced annually using captured CO2, with the remainder safely stored underground.

PRODUCT LIFE CYCLE

Operation Clean Sweep (OCS) is a global program promoting environmental stewardship by helping plastic resin manufacturers and handlers implement best practices for resin containment. CIAC Plastics Division members commit to responsible resin management in line with Responsible Care principles.

In 2024, Plastics Division members reported 75 kg of resin spilled – 81 per cent less than in 2023 and 99 per cent less than in 2021. Of the total spilled, 2024 reported 50 per cent less incidents than in 2023. Members remain dedicated to preventing plastic resin from entering the environment.

In 2024, NOVA Chemicals launched its Canadian Centre of Excellence for Plastics Circularity. This Centre will serve as a hub for knowledge exchange and technology development for the circular economy for plastics with a focus on research and development and value chain-integrated solutions.

Responsible Consumption and Production

Through the NERM survey, CIAC tracks members’ releases of NERM substances to water. These include substances like acids and bases, metal ions and solvents used in various industrial settings. As seen in Figure 7, since 2005, CIAC members have reduced total emissions to water by 75 per cent. In 2023, water emissions represented only 0.0018 per cent of the total emissions reported to all media (i.e., air, land, and water).

NERM also allows CIAC to track members’ water intake from ground, municipal, and surface water sources. A breakdown of water intake by province and source (i.e., ground water, municipal water, and surface water) can be seen in Figure 8, with surface water being the most common source for CIAC members.

CIAC members believe that this resource is precious, which is why many CIAC members are returning water cleaner than when they found it. Figure 9 shows the various water treatment methods used by CIAC members, with 79 per cent of the effluent volume treated on site at member facilities. These treatment measures contribute towards continued availability and sustainability of Canada's water resources in accordance with UN sustainable development goal #6.

Our members have also established ambitious programs to limit waste disposal to landfills. Figure 10 captures the varieties and combinations of methods used to treat this waste. The largest category was a combination of recycling and incineration. Twenty-three out of 31 respondents indicated they used recycling to treat a portion of their waste.

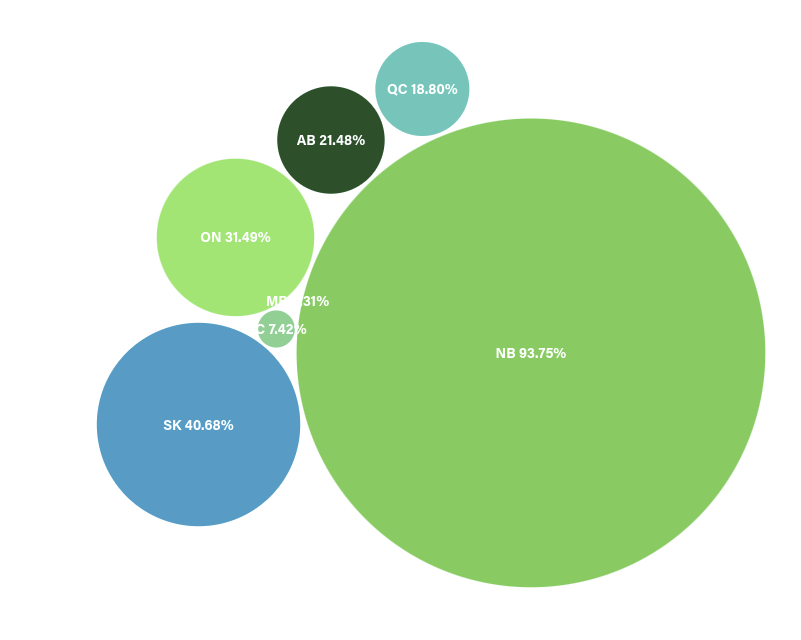

Figure 11 shows the average recycling rates of member facilities by province in 2023. Bubble size corresponds to the average recycling rate of member facilities in that province (percentage of total material recycled/total waste generated). The average recycling rate was 20 per cent in 2021, 26 per cent in 2022, dipping slightly to 25 per cent in 2023.

After several dry years and El Niño producing a warm, dry winter across Canada, Alberta is at risk of severe droughts this year, especially in southern Alberta. To help, 38 of the largest and oldest water licensees in southern Alberta (including CIAC members NOVA, Dow, INEOS and MEGlobal) have voluntarily agreed to reduce the water they use if severe drought conditions develop this spring or summer.

Plastic waste and low-value heavy oils pose significant environmental and economic challenges. Traditional recycling and refining processes are often energy-intensive and inefficient. Aduro has recently introduced it’s Hydrochemolytic™ Technology (HCT) which offers an alternative approach by using water-based chemistry to break down plastic waste and low-value hydrocarbons at lower temperatures and pressures. This process produces high-quality feedstocks for new materials and fuels, contributing to a more sustainable and circular economy while reducing waste and emissions.

Health and Safety

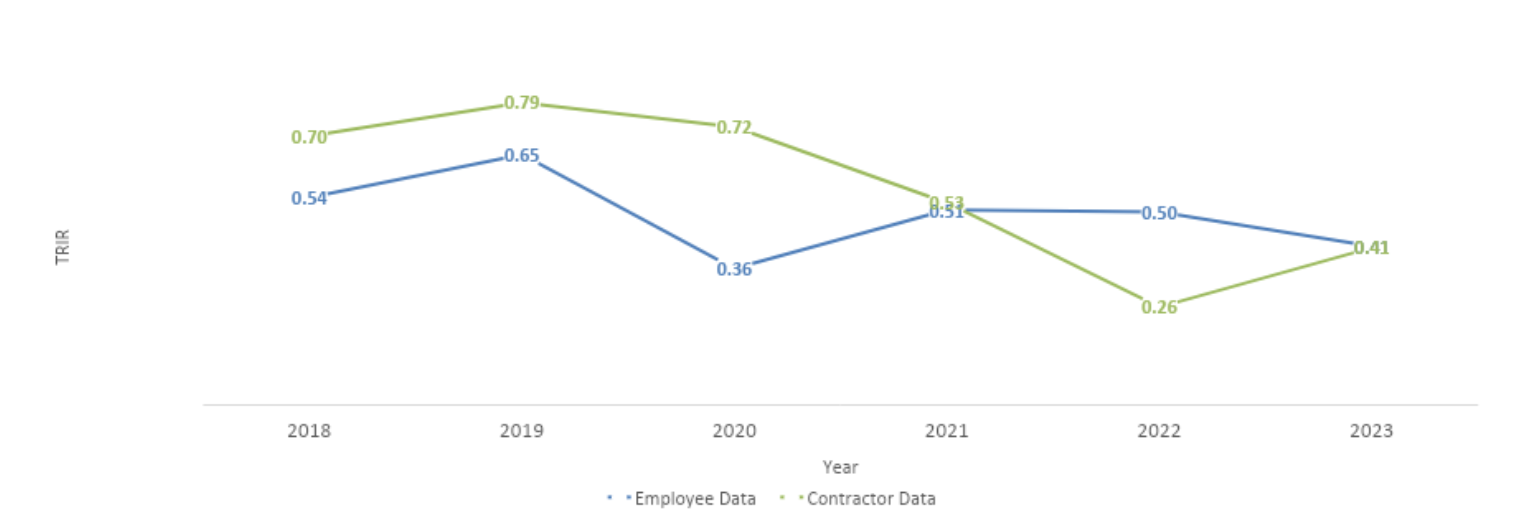

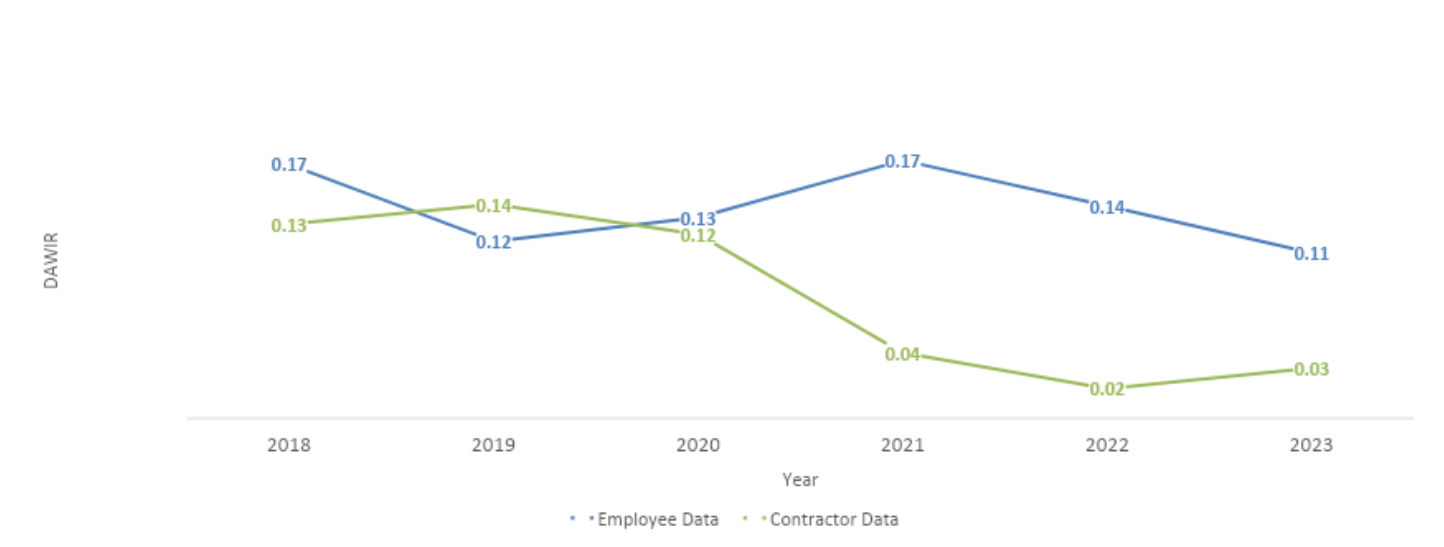

For 40 years, CIAC members have prioritized workplace health and safety. Through the SHARE network, health and safety professionals collaborate to track, measure, and improve performance, aiming for zero workplace injuries and illnesses.

CIAC collects Safety and Health Incident Metrics (SHIM) data annually to monitor health and safety trends. This data helps member companies expand their safety programs and protect everyone involved in the chemistry industry. Trends in the Total Recordable Incident Rate (TRIR) and Day Away from Work Incident Rate (DAWIR) for CIAC member company employees and contractors from 2018–2023 are shown in Figures 12 and 13.

To protect workers, the public, and the environment, all CIAC member companies must have comprehensive process safety management systems aligned with standards from the Canadian Society for Chemical Engineering. Any gaps between a company’s system and these standards must be identified, and action plans developed to raise process safety to an acceptable level. A thorough review of a company's process-safety system is a core part of the Responsible Care verification or audit process.

CIAC collects Process-Related Incident Measures (PRIM) data annually using the Center for Chemical Process Safety (CCPS) metrics, enabling companies to track performance against industry trends and identify areas for improvement. Figure 14 highlights insights from the annual PRIM survey. Since the classification system for process safety events changed in 2016, the number of Higher Learning Value (HLV) events has increased, surpassing Tier 1 and Tier 2 events.

MEGlobal Canada ULC successfully completed its "Don't Skip a Step" Environment, Health, and Safety (EH&S) campaign. Initiated on November 13, 2024, the campaign aimed to reinforce the company's commitment to maintaining a safe and sustainable workplace for all employees and contractors. Throughout the campaign, the EH&S team conducted multiple meetings across all North American sites, ensuring that every employee had the opportunity to participate and contribute to the initiative. Employees and contractors were presented with road safety kits, first aid kits, and fire extinguishers upon the campaign's completion.

Committed to CIAC Responsible Care, with an emphasis on product awareness and safe handling practices across the supply chain, NorFalco (a Glencore company) hosted a sulphuric acid safety and technical seminar in October 2024. This complimentary, one-day seminar was offered to customers, service providers, and emergency response networks. The training covered various topics, including chemical properties, personal safety, transportation handling equipment and design, personal protective equipment (PPE), first aid, and more.

Maintaining a mindset of “chronic unease” is essential to safeguarding people and operations. To reinforce this, Methanex launched a year-long Process Safety Fundamentals campaign in 2024, targeting front-line operations, maintenance, and engineering teams. The initiative focused on identifying situations that could lead to process safety incidents, emphasizing a back-to-basics approach to preventing high-potential events with catastrophic consequences.

Reaching over 1,400 employees and contractors, the campaign engaged workers through regular discussions, monthly quizzes, and town halls. It highlighted ten key process safety principles, including hazard identification, adherence to procedures, managing changes, and maintaining critical barriers. Branded “Connecting the Dots to Protect Lives,” the initiative encouraged experience-sharing and vigilance, ensuring that lessons from past incidents strengthen safety practices across all levels.

TRANSPORTATION

In 2024, the TRANSCAER® team successfully completed the construction of the new Safety Train, with work beginning in July 2023. Significant progress was made in installing valves and fittings on the tank car, as well as completing the platforms and structural components. After years of careful planning, design, and material sourcing, CIAC is excited to launch the new TRANSCAER Safety Train in 2025. The Safety Train will travel across Canada, visiting communities where dangerous goods are transported, to raise awareness about rail safety and emergency response to dangerous goods transportation incidents. CIAC members, partners, and first responders can request the Safety Train for local events through transcaer.ca.

In 2024, TRANSCAER hosted 44 community events with over 830 participants to promote TRANSCAER and help train first responders in the transportation of dangerous goods. This included an event in Laurier Station, Quebec, in April, where 75 first responders from seven municipalities came together for an essential training session on railway safety and dangerous goods response. And in May, at the Canadian Emergency Response Contractors Alliance’s Semi-Annual General Meeting at the Saskatoon Fire Department Regional Training Facility, 39 instructors and volunteers were joined by 77 participants.

COMMUNITY EVENTS

PARTICIPANTS

LOCAL FIRST RESPONDERS IN LAURIER STATION

LOCAL INSTRUCTORS IN SASKATOON

TRANSCAER Award recipients are recognized for their demonstrated exceptional dedication to the program in one of three award categories: distinguished service, national achievement, and regional achievement. The winners from the previous year were announced in June 2024:

Distinguished Service Award

National Service Award

Don Schuilenberg

Operations Manager/ Safety Officer, Rapid Response Industrial Group

Reg Foster

Director, Rapid Response Industrial Group

Randy Mak

Retired, Dow Chemical

Curtis Myson

Dangerous Goods Specialist, Railway Association of Canada

Jean-Pierre Couture

TDG Specialist, Railway Association of Canada

Shaune Zeleny

Regional Manager, Specialized Services and Emergency Response, Western Canada, GFL Environmental Services Inc

Blair Hetherington

Emergency Response Systems Manager, Chemtrade Logistics

Matt Leigh

Senior Dangerous Goods Officer & Wildland Fire, CN Railway

Evan Foley

Emergency Management and Hazmat Officer